The global swimwear market is currently experiencing a massive surge, driven by the rise of “slow fashion,” body positivity, and specialized niche brands. But unlike a standard T-shirt or a tote bag, bikini manufacturing is an intricate engineering challenge.

When you are dealing with such small amounts of fabric, there is zero margin for error. A millimeter of misalignment in a seam or a slightly loose elastic can result in a garment that fails in the water.

If you are developing your first bikini collection, this guide will take you through the entire bikini manufacturing process.

The Bikini Manufacturing Process:

- Tech Pack

- Fabric Sourcing

- Pattern/Fit

- Sampling/PPS

- Bulk Production

1. The Design and Tech Pack Phase

Every successful bikini starts with a Tech Pack. In the swimwear world, your tech pack is your “blueprint.” Because bikinis are high-stretch garments, you cannot simply send a photo to a factory and hope for the best.

What Your Swimwear Tech Pack Must Include:

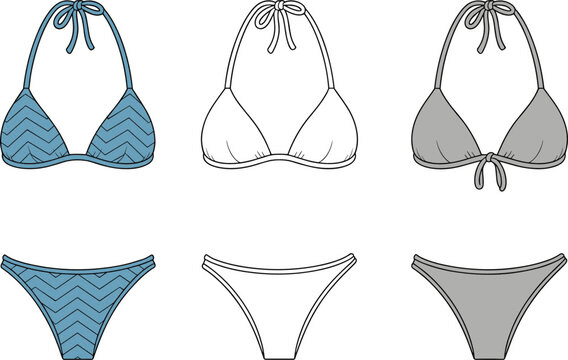

- Technical Sketches: Front and back views with “callouts” for specific seams.

- Bill of Materials (BOM): Every single component, from the main fabric to the thread type, hygiene liners, and metal sliders.

- Point of Measure (POM): Specific measurements for every size, including “relaxed” and “extended” stretch measurements.

- Stitch Requirements: Specifying a zig-zag stitch vs. a flatlock seam is critical for stretchability.

2. Choosing the Right Fabric

Fabric choice is the most important decision in bikini manufacturing. Swimwear is subjected to “the four enemies”: Chlorine, UV rays, Saltwater, and Sunscreen.

High-Performance Options:

- Nylon/Spandex (Lycra): The industry standard. It’s soft, has a beautiful sheen, and offers 360-degree stretch.

- polyester/Spandex:A high-performance choice, more durable than nylon and quick-drying, ideal for swimwear used in high-frequency pool environments.

- PBT (Textured Polyester): As we discussed in our previous guide, PBT is the choice for “Endurance” lines. It is virtually chlorine-proof and holds its shape for years.

- Sustainable Fabrics (ECONYL®): Many modern brands are moving toward ECONYL, a regenerated nylon made from discarded fishing nets and ocean plastic.

Weight (GSM) Matters

For bikinis, you typically want a fabric weight between 180 GSM and 220 GSM. Anything lighter will become transparent when wet; anything heavier will feel bulky and take too long to dry.

3. Pattern Making and Grading

Pattern Making

Pattern making for swimwear is unique because of the “Stretch Factor.” If a bikini bottom is meant to fit a 90cm hip, the actual fabric pattern might only be 75cm wide. This is called negative ease. A pattern maker must calculate the exact percentage of stretch in your specific fabric to ensure the garment stays on the body when it gets heavy with water.

Grading Small Sizes

Grading (creating sizes S, M, L, XL) is particularly difficult with bikinis. Because the pieces are small, the jump between sizes must be calculated with extreme precision to avoid “the gap” in the leg opening or the waist.

4. Specialized Hardware and Trims

A bikini is more than just fabric. To master manufacturing, you must source “swim-grade” hardware:

Rings and Sliders: Must be nylon-coated or specially treated metal to prevent rusting or overheating in the sun.

Bra Cups: Should be water-resistant (so they don’t act like sponges) and removable via a small “pocket” in the lining.

Rubber Elastic: Unlike standard cotton elastic, Framilon or rubber elastic is used in the seams to ensure the bikini “grips” the skin and doesn’t sag.

5. The Manufacturing Process: Step-by-Step

Once your PPS (Pre-Production Sample) is approved, the factory moves into bulk production.

Step 1: Precision Cutting

Because swimwear fabric is “slippery,” factories often use vertical CNC cutters or die-cutting to ensure every piece is identical.

Step 2: Specialized Sewing Machines

You cannot sew a bikini with a standard home sewing machine. It requires:

- Overlock Machines: To finish the edges while allowing for stretch.

- Zig-Zag Machines: For attaching elastic to the leg and waist openings.

- Coverstitch Machines: For professional, flat hems.

Understanding Swimwear Stitch Types

Step 3: Hygiene Liner Application

A crucial (and often overlooked) step. Every bikini bottom must have a self-adhesive hygiene liner applied before packaging.

6. Quality Control

In swimwear manufacturing, Quality Control (QC) goes beyond just looking for loose threads.

A professional manufacturer will perform:

- Stretch Recovery Test: Stretching the fabric to its limit to see if it returns to its exact original shape.

- Colorfastness Test: Ensuring the neon pink doesn’t bleed onto the white contrast panels when wet.

- Crocking Test: Rubbing the fabric to see if the print or color transfers onto skin or towels.

7. Working with Manufacturers

When looking for a partner, you can decide between two types of manufacturing:

| Feature | CMT (Cut, Make, Trim) | FPP (Full Package Production) |

| Responsibility | You provide fabric/trims. | Factory sources everything. |

| Control | High (you pick every detail). | High |

| Best For | Established brands with a supply chain. | Startups and newcomers. |

Pro Tip: Look for a factory that specializes exclusively in swimwear. The precision required for a bikini is very different from that of outerwear or denim.

Top 10 Swimwear Manufacturers in the World

Summary

Mastering bikini manufacturing isn’t about the flashiest designs; it’s about the fit and the longevity. A customer might buy a bikini because it looks good on a screen, but they will only come back to your brand if it stays in place during a dive and doesn’t fade after two weeks at the beach.

Now that you understand how bikini production works, you’re ready to move forward with your next collection. We support you end to end, from design and fabric selection to sampling, bulk production, and shipping. Contact us today and let’s turn your ideas to life .