Choosing the right bikini size strategy is one of the most common challenges for swimwear brands, especially during sampling and early production runs. What looks like a simple S–M–L decision often turns into fit complaints, re-sampling costs, or size inconsistency once bulk production begins.

If you’re running into questions around size grading, you’re not alone. From the factory side, we’ll break down how bikini sizing is handled in production, how grading affects fit, and what’s worth confirming early so sampling and bulk stay consistent and your launch goes smoothly.

What “Bikini Size” Means in Manufacturing

In retail, bikini size is usually reduced to labels like S, M, or L. In manufacturing, sizing is much more technical.

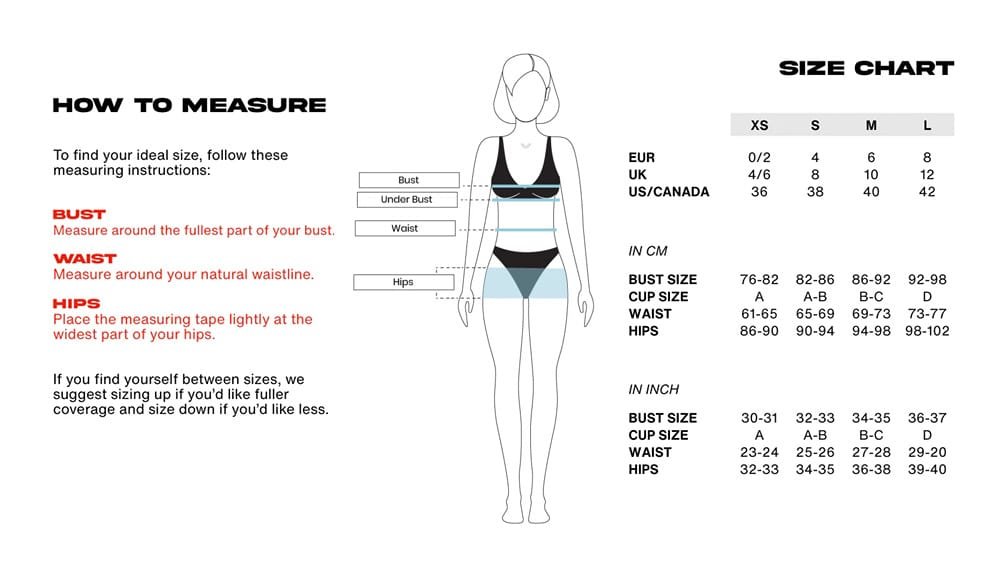

A bikini size is defined by measured dimensions, not letters. These typically include:

- Bust and underbust

- Waist and hip

- Cup depth and coverage

- Strap length and elasticity

- Bottom rise and side width

Two bikinis labeled “M” can fit very differently if these measurements are handled differently during pattern making and grading. This is why factories work from measurement tables and base patterns, not from size labels alone.

Understanding this difference early helps brands avoid unrealistic fit expectations later.

Standard Bikini Size Ranges Used in Production

Most factories follow international sizing logic, but there is no single universal standard. Sizes are usually aligned loosely with US, EU, UK, or AU systems, then adjusted based on the brand’s target market.

In production, factories typically:

- Start with one base size (commonly S or M)

- Build a full size range by grading up and down from that base

- Adjust key points rather than scaling all measurements evenly

The important takeaway is that size labels are descriptive, not absolute. What matters is whether the measurements match your customer profile.

How Bikini Size Grading Works (From Sample to Bulk)

Size grading is the process of scaling a pattern into multiple sizes while maintaining fit balance.

In swimwear, grading is more complex than in T-shirts or hoodies because:

- Fabric stretch affects how size increases feel on the body

- Tops and bottoms behave differently

- Small changes in cup depth or rise height can dramatically change fit

In practice:

- Hip width and bottom coverage usually increase faster than bust

- Strap length and tension must be adjusted carefully

- Vertical measurements (rise, torso length) cannot be graded blindly

When grading is done poorly, brands often see issues like straps digging in, bottoms rolling, or tops losing support in larger sizes. These are grading problems, not sewing problems.

Common Bikini Fit Problems Brands Encounter

From a manufacturing perspective, most bikini fit complaints fall into a few predictable categories:

- The sample fits well, but bulk sizes feel inconsistent

- Bottoms fit as expected, but tops feel tight or unstable

- Fit changes after lining, elastic, or printing is added

- Models approve fit, but real customers experience discomfort

In most cases, the root cause is misaligned size grading or unclear fit direction, not fabric quality or workmanship.

Bikini Fit Tips for Brand

Before approving a sample or moving into bulk, experienced buyers usually focus on the following:

- Approve a fit sample, not just a photo or sales sample

- Decide early whether the style prioritizes top support, bottom coverage, or a balanced fit尽

- Define your target body type clearly (fashion fit vs commercial fit)

- Test stretch recovery, not only static measurements

- Confirm acceptable measurement tolerances for bulk production

These steps reduce rework, shorten timelines, and prevent post-delivery disputes.

Choosing the Right Size Range for Your Bikini Collection

Not every brand needs a full size run from XS to XXL. The right size range depends on your market and production stage.

For many emerging brands:

- Starting with 3 sizes (for example S–M–L) keeps MOQ and cost under control

- Expanding to XL or extended sizes can be planned after initial sales feedback

- Each additional size increases complexity in grading, inventory, and QC

From a factory standpoint, clear size planning upfront helps control costs and avoid unnecessary revisions.

How We Handle Bikini Size & Fit as a Manufacturer

In real production, size and fit are managed as a process, not a single approval step.

Our typical approach includes:

- Developing a base size pattern aligned with the brand’s target market

- Reviewing size grading logic before full size development

- Using fit samples to test real wear, stretch, and recovery

- Communicating adjustments clearly before bulk production

- Monitoring size tolerances during production, not after delivery

This process reduces surprises and ensures that the final product matches what was approved during sampling.

FAQs

Most new brands start with 2–3 core sizes and expand once sales data is available.

Yes. Factories can develop patterns based on your reference samples or measurement tables.

Usually S or M, depending on the target customer and market.

This depends on the style and fabric, but tolerances should be defined and agreed on before bulk.

Yes. Stretch ratio, recovery, and lining all influence final fit and should be tested during sampling.

Final Thoughts

A successful bikini collection is not defined by how many sizes you offer, but by how well those sizes fit your customer. Clear size planning, realistic grading, and proper fit testing are what separate smooth productions from costly revisions.

If you are developing a new bikini collection or seeking to rectify sizing inconsistencies from previous suppliers, as China’s premier swimwear manufacturer, we can assist in formulating practical grading plans, fitting procedures, and volume tolerance standards tailored to your target market and fabric selection.