The global swimwear market has reached a pivotal moment in 2026. No longer is it enough to simply produce a “pretty” bikini. Today’s consumers demand high-performance fabrics, radical supply chain transparency, and inclusive sizing that actually fits.

For a brand owner, the most critical decision you will make—far more important than your logo or your Instagram aesthetic—is choosing the right manufacturing partner.Whether you are a startup looking for low MOQs or a scaling brand seeking a high-volume factory, this guide will provide the technical and strategic framework you need to find the perfect bathing suit manufacturer.

Where Should You Produce in 2026?

In 2026, the geography of swimwear manufacturing has shifted. While China remains the powerhouse, other regions have carved out specific niches based on sustainability, craftsmanship, and speed-to-market.

China: The High-Tech Efficiency Leader

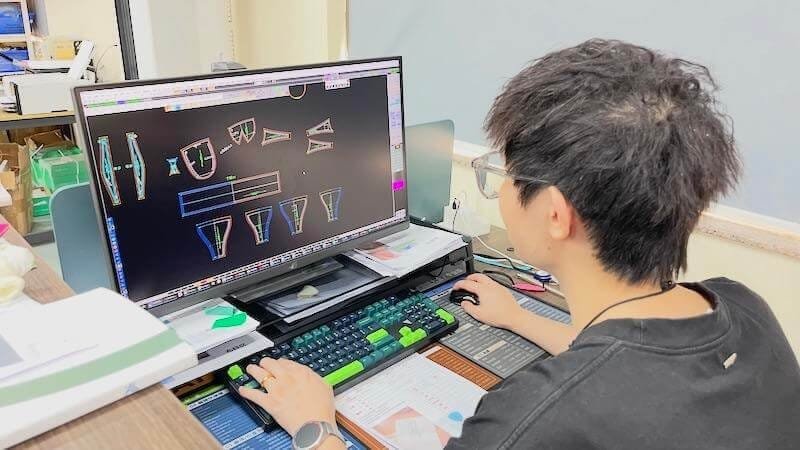

China has reinvented itself. The “cheap and low quality” stigma is a thing of the past. In 2026, Chinese factories are the leaders in digital-first manufacturing.

- Best for: Scale, complex technical construction, and innovative fabric sourcing.

- Pros: Incredible infrastructure, access to the latest recycled nylon blends, and highly efficient logistics.

- Cons: Geopolitical trade tensions can lead to fluctuating tariffs.

Bali & Indonesia: The Sustainable Boutique Choice

Bali has become the global hub for “Eco-Luxe” swimwear. Most factories here focus exclusively on high-end, sustainable brands.

- Best for: Premium brands, influencers, and brands prioritizing ECONYL® or REPREVE®.

- Pros: Exceptional craftsmanship, ethical labor standards are often a core selling point, and highly aesthetic “Instagram-ready” products.

- Cons: Higher per-unit costs and longer shipping times to the US and Europe.

Brazil & Colombia: The Design & Fit Experts

South American manufacturers have an inherent “DNA” for beachwear. Their understanding of fit, particularly for cheeky and Brazilian cuts, is unmatched.

- Best for: Fashion-forward brands, high-vibrancy prints, and hardware-heavy designs.

- Pros: Unique hardware (gold-plated, heat-resistant) and a “flair” for design that Asian factories sometimes lack.

- Cons: Can be difficult to navigate without Spanish or Portuguese language skills.

USA & Europe: The “Near-Shoring” Revolution

With the rise of “Slow Fashion” in 2026, many brands are moving production closer to home to reduce their carbon footprint and increase speed-to-market.

- Best for: Small-batch drops, “Made in USA/UK/EU” prestige, and rapid restocking.

- Pros: Extremely fast shipping, easier quality oversight, and “Made Local” marketing power.

- Cons: The highest labor costs in the world.

What Makes a Great Swimwear Factory?

Unlike a standard garment factory, a swimwear manufacturer needs specialized machinery and a deep understanding of “Stretch Physics.” When vetting a factory, ask for proof of the following:

Specialized Machinery

- Four-Needle Six-Thread (Flatlock) Machines: Essential for performance swimwear. This creates a flat, “frictionless” seam that won’t chafe the skin.

- Zig-Zag & Coverstitch Machines: Necessary for attaching elastic to leg and waist openings while maintaining 100% stretch recovery.

In-House Testing Lab

A professional manufacturer should test your fabric for:

- Chlorine Resistance: Does it degrade after 50 hours of pool exposure?

- Crocking: Does the color rub off on white towels?

- Saltwater Degradation: Do the metal rings and sliders rust?

Pattern Grading Expertise

Bikini sizing is notoriously difficult. A great factory will have an in-house pattern maker who understands Negative Ease—the science of making a garment smaller than the body so it stays on when wet.

Understanding Pricing and MOQs in 2026

Pricing in 2026 is no longer just about “Labor + Materials.” It is about the “Full Package.”

Typical Cost Breakdown:

- Fabric (30-40%): High-quality recycled Italian nylon will cost significantly more than standard Chinese polyester

- Labor (30%): Varies by region.

- Development & Sampling (10%): Includes Tech Pack creation and 3D modeling.

- Logistics & Duties (20%): Often overlooked but can kill your margins if not calculated upfront.

The MOQ (Minimum Order Quantity) Reality

- Startup Friendly: 50–100 pieces per style – Usually found in China or Bali.

- Mass Market: 300–500 pieces per style – Usually European or Vietnamese FPP factories.

- Warning: Beware of factories offering “Ultra-Low” MOQs (under 20 pieces) at low prices—they often skip essential steps like stress-testing seams or using swim-grade elastic.

How to Start: The Step-by-Step Process

Step 1: The RFQ (Request for Quotation)

Don’t just send an email saying “How much for a custom bikini?” Send a professional RFQ package including:

- Tech Pack or Reference Image.

- Estimated Order Quantity (per size and per color).

- Fabric Preference (e.g., “Looking for 80% Recycled Nylon, 20% Spandex, 220 GSM”).

- Target Delivery Date.

Tip: The more information you provide, the more manufacturers will view you as a highly valued customer. They will be more patient in answering your questions and offer professional advice tailored to your needs.

Step 2: The Proto-Sample

Order a sample. This is your first test of the factory’s communication and quality.

- Check: Are the seams straight? Does the elastic “snap back” instantly? Is the lining the same quality as the outer shell?

Step 3: The Factory Audit

In 2026, you cannot afford a “sweatshop” scandal.If you can’t visit the factory in person, you can tour it online directly.

- Social Compliance: Fair wages and safe working conditions.

- Environmental Impact: How do they handle fabric scraps and chemical dyes?

Red Flags to Watch Out For

- “Yes to Everything”: If a factory says they can do any design, any fabric, and any price without asking for a Tech Pack, they are likely over-promising and will under-deliver.

- Slow Communication: If it takes them a week to reply to an email during the “sales phase,” it will take a month when there is a production problem.

- Lack of Specialized Hardware: If they suggest using “regular” metal rings (not nylon-coated or heat-treated), your customers will end up with rusty suits and burnt skin.

- Vague Sourcing: If they can’t tell you exactly which mill their fabric comes from, it’s likely not sustainable or high-performance.

Conclusion

The most successful swimwear brands in 2026—from giants like Speedo to indie favorites like Monday Swimwear—view their manufacturers as partners, not just vendors.

When you find a factory that understands your vision, respects your quality standards, and communicates transparently, protect that relationship. Pay your invoices on time, provide clear feedback, and grow together. In the volatile world of fashion, a reliable manufacturer is your most valuable asset.