Choosing a swimsuit manufacturer is a high-impact decision for any swimwear brand. The right partner protects your product quality, delivery timelines, and customer experience. The wrong one can lead to fit issues, inconsistent materials, delayed shipments, and costly rework that quickly eats into your margins.

If you’re sourcing for a new collection or considering switching suppliers, the real goal is not to find the cheapest option. It is to reduce risk before you invest time and money into sampling and bulk production.

This guide explains what reliability actually means in swimwear manufacturing, and how swimwear brands can evaluate factories with confidence.

What Makes a Swimsuit Manufacturer Reliable?

A reliable swimsuit manufacturer is not defined by a single promise or one successful sample. Reliability comes from systems that work consistently over time.

In practice, most factories can be evaluated using five core criteria:

- Swimwear-specific manufacturing experience

The factory understands stretch fabrics, lining structures, elastic tension, and fit control, not just general apparel sewing. - Real control over sampling and production

Patterns, samples, and production are managed in-house or through a clearly controlled process, rather than loosely outsourced. - Transparent fabric sourcing and material standards

Fabric composition, specifications, and sourcing are clear, with consistent availability for reorders and scalability. - Defined and enforceable quality control procedures

The factory can explain what is checked, when it is checked, and how issues are handled before shipping and after delivery. - Professional communication and realistic lead times

Timelines are achievable, communication is consistent, and potential issues are communicated early rather than at the last minute.

If a manufacturer meets these five standards, the likelihood of quality disputes, production delays, and unexpected costs drops significantly.

The sections below explain how to verify each point in practice.

Quick evaluation checklist

- Confirm they are a real manufacturer, not only a trading company

- Ask technical swimwear construction questions and assess the clarity of answers

- Request a clear sample timeline, revision process, and cost breakdown

- Verify fabric specifications, sourcing consistency, and certifications

- Understand their quality control workflow and defect handling process

Understand Your Manufacturing Needs

Before contacting any manufacturer, it is important to clearly define your own requirements. Many sourcing problems arise not because a factory is unreliable, but because it was never the right match.

Start by clarifying:

- Your target market (mass market, mid-range, or premium)

- Expected order volume per style

- Design complexity, such as custom prints, hardware, embroidery, or shaping

- Compliance or sustainability requirements

- Target delivery schedule

A factory that excels at high-volume basic styles may struggle with low-MOQ, design-driven collections. Likewise, a development-focused factory may not be optimized for large seasonal volumes. Clear internal requirements help you filter factories faster and avoid wasted time on both sides.

Manufacturer vs Trading Company

One of the first things brands should confirm is whether they are dealing with a real manufacturer or a trading company.

A genuine swimsuit manufacturer usually:

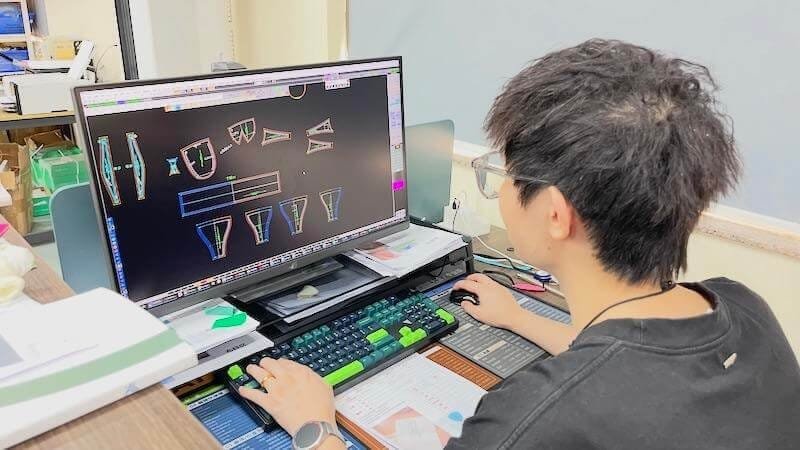

- Has in-house pattern making and sampling

- Controls production lines directly

- Manages quality control internally

- Can explain technical construction details without hesitation

Trading companies often coordinate production across multiple factories. This model can work for simple products, but it typically introduces:

- Less direct quality control

- Longer communication chains

- Slower problem resolution

- Higher risk for complex swimwear designs

A simple test is to ask detailed questions about swimwear construction. A real manufacturer can explain stitching methods, elastic application, lining options, and fit adjustments clearly and consistently.

Check Swimwear-Specific Experience

Swimwear is not the same as general apparel. Fabric behavior, fit tolerance, and construction standards are very different from T-shirts or activewear.

A reliable swimsuit manufacturer understands:

- Stretch and recovery performance

- Lining coverage and structure

- Elastic tension and durability

- Stitching suitable for water exposure

- Fit grading across sizes

Ask how long the factory has focused specifically on swimwear, not just clothing overall.

Also ask what categories they regularly produce, such as bikinis, one-piece swimsuits, men’s swimwear, or kids’ swimwear. Experience in your specific category reduces the chance of avoidable mistakes during sampling and bulk production.

Evaluate Sampling Capability and Development Process

Sampling is where trust begins.

A professional manufacturer should clearly explain:

- Sample lead time

- What affects sample cost

- Whether patterns are created from scratch

- How many revisions are included

- How fit feedback is handled

Sampling should feel structured, not improvised. You should receive clear updates and know exactly what happens after each revision.

Be cautious of factories that promise extremely fast samples without reviewing your design details.

In swimwear, rushed samples often hide problems that surface later during bulk production.

Fabric Sourcing and Material Transparency

Fabric quality is at the core of swimwear performance and customer satisfaction. A reliable manufacturer is transparent about materials.

Key points to confirm:

- Fabric composition and weight

- Stretch, recovery, and durability

- Colorfastness and print stability

- Sourcing consistency for reorders

- Availability of recycled or certified options

Instead of listing dozens of fabric names, strong manufacturers focus on explaining how materials are selected, tested, and controlled across production runs. If sustainability is important to your brand, ask how certifications are verified and whether documentation can be provided.

Quality Control Standards You Should Ask About

Many factories say they have strict quality control. What matters is how that control is implemented.

Useful questions include:

- Is there in-line inspection during production?

- Are fit and measurements checked before bulk cutting?

- How are defects identified and recorded?

- Is final inspection done before packing?

- What is the process if issues are found after delivery?

Reliable manufacturers are comfortable explaining their QC workflow in detail. Clear answers indicate accountability and experience.

Communication, Lead Time, and Reliability

Communication quality often matters as much as technical ability.

Pay attention to:

- Response speed and clarity

- Willingness to explain technical details

- Consistency of contact person

- Realism of promised timelines

Factories that overpromise often cause more problems than those that give conservative but achievable schedules. A reliable partner communicates early when issues arise and works with you to adjust, rather than staying silent until the deadline passes.

Certifications, Compliance, and Export Experience

Depending on your target market, certifications may be required or strongly preferred.

Rather than asking only whether certifications exist, ask:

- Which certifications are relevant to your market

- How often audits are update

- Whether test reports can be shared

- Experience exporting to your target region

Export experience is especially important for B2B buyers. Familiarity with shipping documentation, customs requirements, and packaging standards reduces friction and delays.

Red Flags When Choosing a Swimsuit Manufacturer

Certain warning signs appear repeatedly in failed sourcing projects:

- Prices far below market average without explanation

- Refusal to share factory photos or videos

- Unclear or changing factory address

- Inconsistent answers from different sales contacts

- Copy-paste replies to technical questions

- No written confirmation of sample timelines

Early uncertainty usually grows later. Trust your instincts and verify details before moving forward.

Final Checklist Before You Place a Sample Order

Before committing to samples, make sure you have:

- Confirmed the factory type and location

- Reviewed relevant swimwear experience

- Agreed on sample cost, timeline, and revisions

- Clarified MOQ and bulk pricing structure

- Confirmed fabric sourcing and specifications

- Tested communication efficiency

Treat the sample stage as a small-scale test of the long-term partnership.

Final Thoughts

Choosing a reliable swimsuit manufacturer is not about finding perfection. It is about finding a partner who understands swimwear, communicates clearly, and takes responsibility for the work they deliver.

The most successful manufacturer relationships are built gradually, starting with realistic expectations, structured sampling, and transparent communication. A good factory does more than produce swimwear. It helps brands grow with fewer surprises and better control.

If you are evaluating manufacturers now, start with the right questions and a well-managed sample order. It is the most effective way to move forward with confidence.

FAQs About Choosing a Swimsuit Manufacturer

If you’re at the research stage, the fastest way is to start with a curated list and then shortlist factories based on your product type, MOQ, sampling speed, and compliance needs. We’ve put together a reference list here: Top10 Swimwear Manufacturers in the World.

A reliable swimsuit manufacturer usually has clear swimwear-specific experience, structured sampling and production control, transparent fabric standards, defined quality control steps, and stable, professional communication.

A swimsuit manufacturer controls production directly, often including pattern making, sampling, sewing lines, and quality control. A trading company typically coordinates production through third-party factories.

Before paying for samples, you should ask about sample lead time, what the sample fee includes, how many revisions are allowed, whether patterns are created from scratch, what materials will be used, and how fit feedback will be handled before bulk production.

Before placing a bulk order, confirm the approved sample or tech pack, fabric and trim specifications, size grading, MOQ and pricing structure, production timeline, quality standards, packaging requirements, and how defects or changes will be handled.

Common red flags include prices that are far below market level without explanation, vague or copy-paste answers to technical questions, refusal to share factory proof such as photos or videos, inconsistent communication, and unclear or changing sample timelines.