Whether you’re launching your first swimwear line or managing a growing DTC brand, choosing the right manufacturing partner is one of the most important decisions you’ll make.

A reliable swimwear manufacturer can bring your designs to life with quality, speed, and professionalism — while a poor choice can result in delays, costly mistakes, and damaged brand reputation.

In this guide, we’ll walk you through what to look for in a swimwear manufacturer, the common pitfalls to avoid, and how to properly evaluate a factory’s capabilities — all based on real industry experience.

Why Choosing the Right Swimwear Manufacturer Matters

Swimwear isn’t like casualwear — it involves specific fabrics, stretch recovery, fit precision, and brand consistency. A good manufacturer does more than sew your ideas together — they act as your strategic partner.

The right factory can help you:

- Avoid production delays

- Maintain consistent sizing and quality

- Scale your orders as your brand grows

- Protect your intellectual property

- Ensure ethical and sustainable production

That’s why investing time in selecting the right partner pays off in the long run.

8 Key Factors for Selecting a Swimwear Manufacturer

Let’s break down the key criteria you should assess before making a decision:

1. Low MOQ

If you’re a startup or testing new designs, choose a manufacturer that offers low MOQ — ideally under 100 pieces per design. This allows you to stay flexible with inventory and reduce risk.

Tip: Look for factories that offer 50-100 pcs MOQ for custom swimwear.

2. Sampling Speed & Production Lead Time

Fast sample turnaround (7-15 working days) and clear production timelines (typically 30–40 days) are signs of a well-managed factory. Avoid those who are vague or overpromise.

3. Customizability & Design Flexibility

Do they support custom fabrics, sizes, prints, accessories, packaging, labels, and more? Can they handle complex designs like underwire bikinis, cutouts, or multi-panel construction?

Choose a factory that offers full-package service — from design development to delivery.

4. Sustainability Credentials

If you’re building an eco-conscious brand, verify whether the manufacturer uses recycled fabrics (e.g., Recycled Nylon, Recycled Polyester) and holds certifications such as OEKO-TEX or GRS.

5. Communication & Professionalism

Responsive communication and clear documentation (like tech packs, spec sheets, PO confirmations) can save you from future misunderstandings. Avoid suppliers who often change their answers or lack written processes.

6. Experience with Swimwear

Look at how long the manufacturer has been producing swimwear. Do they have a dedicated team and internal departments (like design, cutting, sewing, QC)? Ask to see previous work and real production photos.

7. Third-Party Audits & Quality Control

Reliable factories welcome third-party inspections or audits, especially before bulk shipment. Some even offer in-house quality reports or pre-shipment photos/videos.

8. NDAs & Confidentiality Agreements

If you’re a designer or building a signature collection, check if the factory is open to signing a non-disclosure agreement to protect your IP.

Industry Pitfalls to Watch Out For

Even experienced buyers fall into these traps — here’s how to avoid them:

Beautiful samples, poor mass production

Some factories assign top workers to samples but cut corners during bulk production. Always confirm PP (pre-production) samples before starting large orders.

Unrealistically low prices

Cheap doesn’t mean efficient. Low quotes may come with long lead times, poor stitching, or fabric substitution.

Greenwashing

Some suppliers claim eco-friendliness without certifications. Always ask for documents like OEKO-TEX, GRS, or fabric test reports.

How to Evaluate a Swimwear Factory’s Reliability

Before committing, here’s how to assess whether a manufacturer is genuinely capable:

✅ Check Their Sample Process

Ask for clear tech packs and spec sheets

Provide a timeline and cost for samples

Offer feedback on construction feasibility

Follow up for confirmation and revisions

✅ Review Their Past Work

Request:

Photos or videos of past swimwear styles they’ve made

Fabric swatch cards or prints they’ve handled

Case studies or references from previous clients

✅ Ask for Certification & Documentation

Request:

OEKO-TEX or GRS certificates

Material composition reports

Third-party QC reports or shipment photos

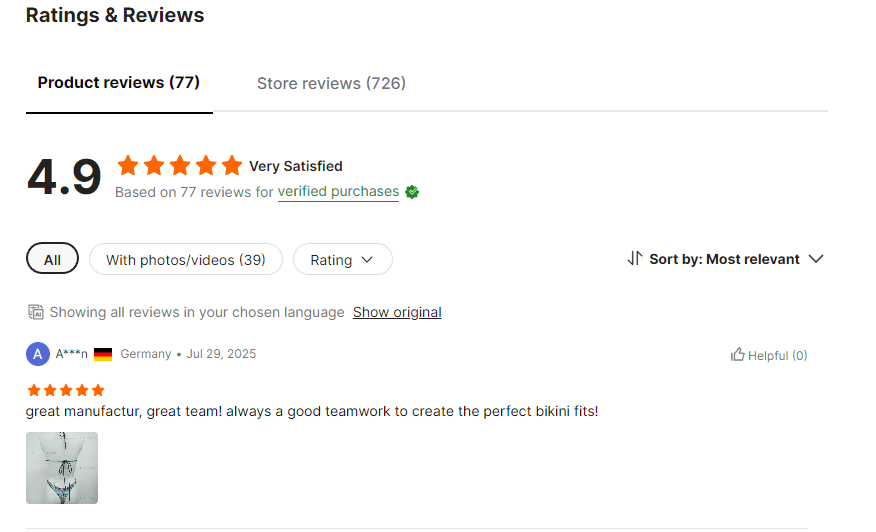

✅ Check Their Online Reputation

If they’re on platforms like Alibaba or Made-in-China, read client reviews. See how they respond to complaints or requests.

Conclusion

A good swimwear manufacturer should grow with your brand — offering quality, flexibility, and consistent support. Don’t rush the decision.

Take time to verify their capabilities, communicate clearly, and invest in a relationship built on trust and transparency.

Whether you’re launching a boutique brand or scaling up an established label, the right partner can be the difference between surviving and thriving in the competitive swimwear market.