Bringing your swimwear designs to life involves more than just inspiration — it takes technical precision, strong communication, and a clear process from concept to delivery. Whether you’re launching your first bikini line or scaling up production for your e-commerce brand, understanding the custom swimwear development journey is essential for success.

In this article, we’ll break down the full process of swimwear manufacturing, from sample development to bulk production, so you know exactly what to expect — and how to avoid costly mistakes.

The Full Swimwear Customization Workflow

Many first-time swimwear brand owners think the process starts with the factory and ends with finished goods — but in reality, each step builds on the last.

Here’s the complete process:

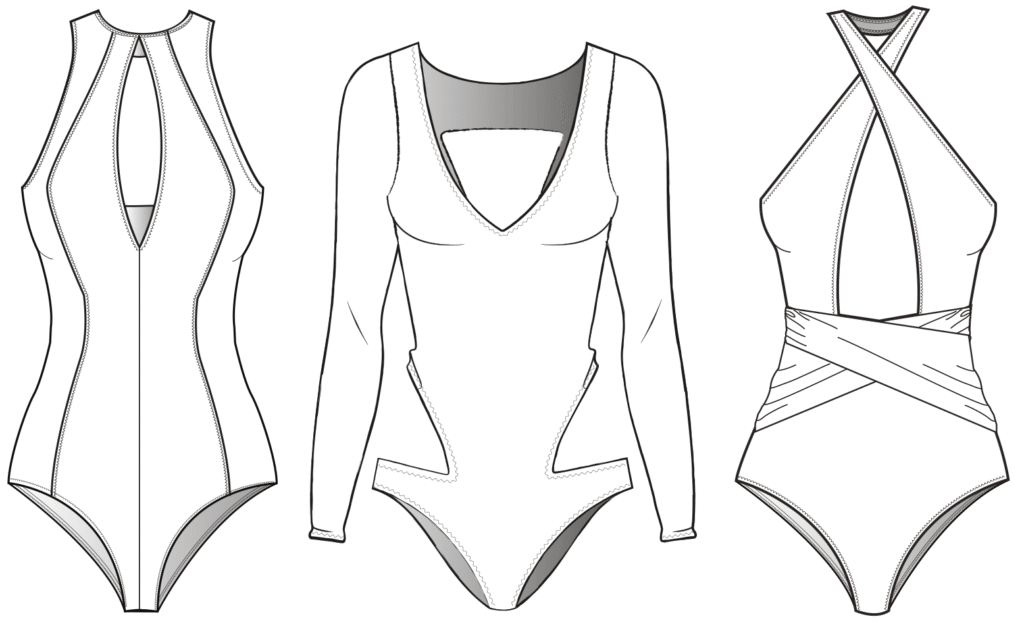

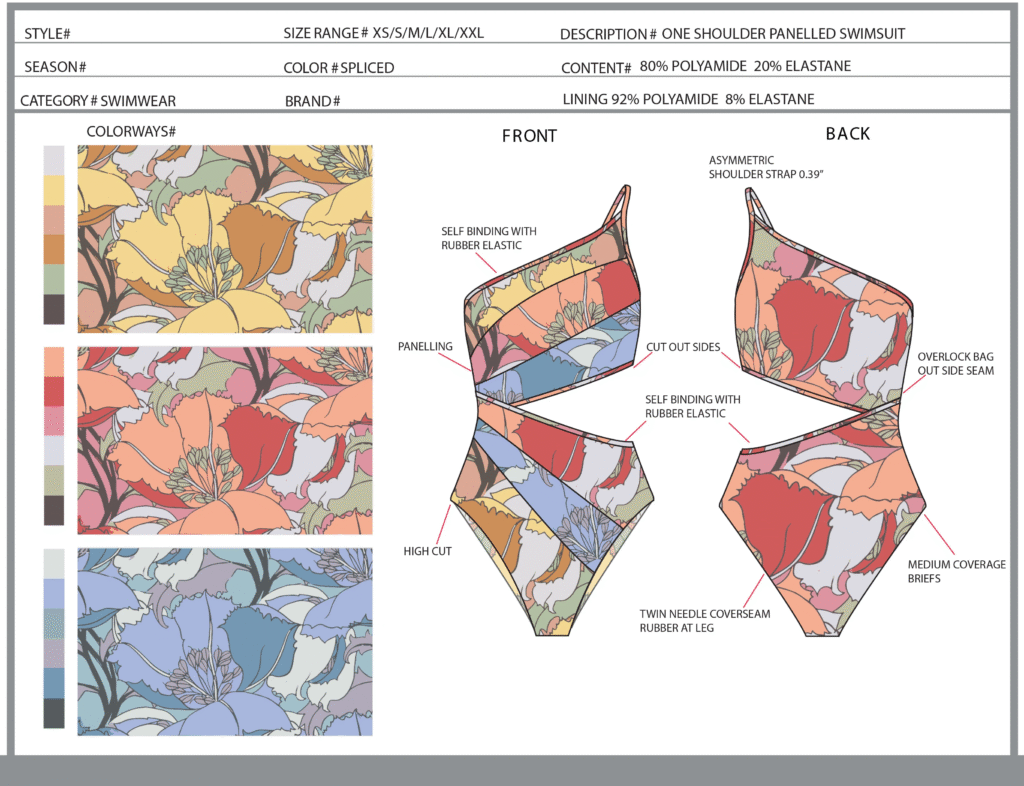

1.Design Confirmation – This includes providing a clear tech pack, design sketches, reference images, or even physical samples. Clarity at this stage is key.

2.Material & Trims Sourcing – The manufacturer will help source appropriate fabrics (e.g., Lycra, recycled nylon, lining) and accessories (pads, hooks, elastic, etc.).

3.Pattern Making – Turning a 2D sketch into a 3D wearable garment through a paper or digital pattern.

4.Sample Development (Initial Sample) – A first physical version of the design is created for review.

5.Feedback & Revisions – Edits are made based on customer feedback. This may involve several rounds.

6.PP Sample (Pre-Production Sample) – The final approved version. Bulk production will follow this sample exactly.

7.Bulk Material Procurement – Materials are ordered in production quantity after PP sample is approved.

8.Cutting, Sewing & Assembly – Garments are produced based on size breakdown and specifications.

9.Quality Control, Pressing & Packaging – Each piece is checked, finished, labeled, packed.

10.Shipping – The final step, based on the agreed logistics method.

Understanding each phase will save you both time and money — especially if you’re working with a custom swimwear manufacturer for the first time.

How Long Does It Take?

Sample Development: 7–15 Working Days

Producing the first sample usually takes 7–15 days, depending on design complexity and material availability. Most manufacturers will charge a sample fee, which is often refundable if you move forward with production.

There are usually two key types of samples:

- Initial Sample: Created to test your design idea and fit. This may go through multiple rounds of changes.

- PP Sample (Pre-Production): A perfected sample that reflects all final design elements — fabrics, trims, construction — and serves as the reference for bulk.

Tip: Make sure you clearly label each revision and track all changes to avoid confusion during bulk production.

What Do You Need to Provide?

To keep the process smooth and efficient, be prepared to provide the following before sampling begins:

- Tech Pack (with detailed measurements, construction notes, and stitching diagrams)

- Size Chart

- Fabric references or requirements (e.g., shiny, matte, recycled)

- Logo files (vector format)

- Label, hangtag, and care tag designs

- Pantone color codes for accurate color matching

Missing or unclear documentation is one of the biggest causes of delays or miscommunication. It’s essential to communicate clearly with your factory and answer their clarifying questions early on.

Sample vs. Bulk: What Changes, What Stays the Same?

While the construction methods stay consistent, there are two important differences between sampling and bulk production:

Fabric Variation (Color Lots): Sampling may use small-batch or leftover fabric from a different dye lot, so the bulk fabric (even if the same type) may look slightly different. This is known as dye lot variation or “cylinder color difference.”

Bulk Efficiency: Some production steps, such as automatic cutting or pressing, may differ slightly from manual sample methods, but won’t affect final quality.

Always inspect your PP sample carefully, as the factory will replicate it exactly — this is your final checkpoint before mass production begins.

✅ Some brands also send samples to third-party labs for stretch, colorfastness, or chlorine resistance testing — especially if the product is for performance use or strict retail standards.

Bulk Production Timeline

Once the PP sample is approved, most swimwear manufacturers require about 30–40 days to complete production.

This varies depending on:

Style complexity: More panels, accessories, or handwork = longer time.

Order size: Small batches may finish sooner.

Seasonality: Factories are busier before peak summer seasons.

Pro tip: Build some buffer into your launch timeline to avoid rushed shipping or quality issues.

Before You Start Production: What Needs to Be Confirmed?

Before giving the green light for bulk production, make sure the following are finalized:

✅ PP sample signed off in writing.

✅ All order details (style code, sizes, colorways, quantities) confirmed.

✅ Label and packaging materials ready.

✅ Payment terms agreed (most factories require 30–50% deposit).

✅ Shipping method selected (air vs. sea, courier vs. forwarder).

Skipping any of these steps can lead to confusion, delays, or worse — receiving 1,000 units with the wrong label.

How to Streamline Your Custom Swimwear Project

Based on real industry experience, here are a few golden rules to help you get the best results from your factory:

- Communicate clearly from day one: Take time to explain your design vision, expected fit, and customer profile.

- Prepare everything in advance: A full tech pack, confirmed size chart, and all logos/tags will save weeks of back-and-forth.

- Avoid excessive changes: Once a sample is confirmed, try not to make changes unless absolutely necessary — it resets the process.

- Ask questions: A good manufacturer will welcome your curiosity and explain anything unclear, from seam types to fabric performance.

Conclusion

Turning your swimwear ideas into real products is a detailed process, but it doesn’t have to be overwhelming. With the right preparation, clear documentation, and a reliable swimwear manufacturer, you can go from concept to shelf with confidence.

Customization is where your brand’s personality shines — and when executed correctly, it creates products your customers love to wear (and reorder).